LDPE (low density polyethylene) is a soft, flexible, lightweight plastic material. LDPE is noted for its low temperature flexibility, toughness, and corrosion resistance. It is not suited for applications where stiffness, high temperature resistance and structural strength are required.

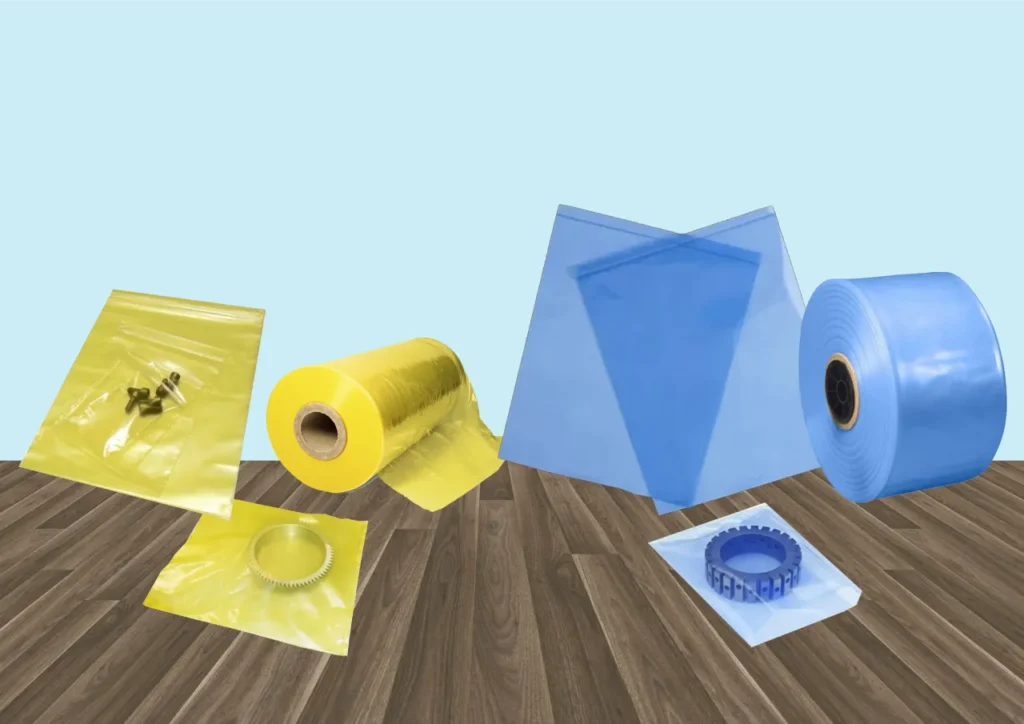

These films are effective in the packaging industry for reasons such as keeping away dust, avoids products sticking to each other, hazardous shocks, damage of the product, etc.

Products that are highly corrosive should be packed in these films to avoid the danger caused from static charges.

These films are used in sealing of food, pharmaceutical products, medicines & tablets, cans, water & in other industrial applications. It is an extremely cost effective form of packaging which conceals the product from contamination.

VCI stands for Vapor Corrosion Inhibitor pouches, are made with poly packaging film converted to a pouches/bag manufactured with added VCI chemistry. VCI bags work by creating a protective barrier around metal parts and equipment, which helps prevent corrosion from occurring. This layer inhibits the corrosion process caused by oxygen, water, and contaminants.

Stretch wrap or stretch film, also known as pallet wrap, is a highly stretchable plastic film that is wrapped around items. The elastic recovery keeps the items tightly bound. In contrast, shrink wrap is applied loosely around an item and shrinks tightly with heat. While it is similar to plastic food wrap. The most common stretch wrap material is linear low-density polyethylene (LLDPE)

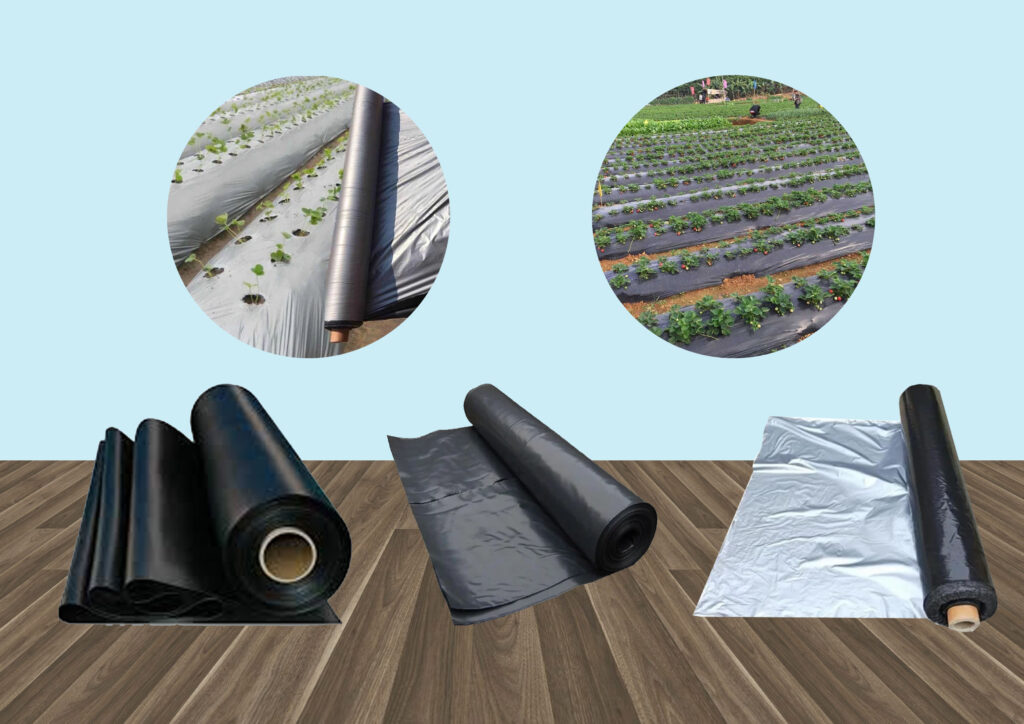

A mulch film is a layer of material applied to the surface of soil and conserve water in crop production and landscaping. Reasons for applying mulch include conservation of soil moisture, improving fertility and health of the soil, reducing weed growth, and enhancing the visual appeal of the area.